Answer the question

In order to leave comments, you need to log in

How to make a mini wind generator from a motor from a printer?

I had an idea - to increase Wi-Fi coverage in the courtyard of a private house. It is necessary to power the Wi-Fi repeater, which will be installed on the outbuilding on the other side of the site. I don't want to bring food from home. So I decided to make a mini windmill. I just have a couple of motors from the printer (QK1-1263):

The repeater, as I read from the Internet, will not consume more than 3 watts, and even then this is under heavy load. And how many watts will this motor give? Is one enough to power the repeater?

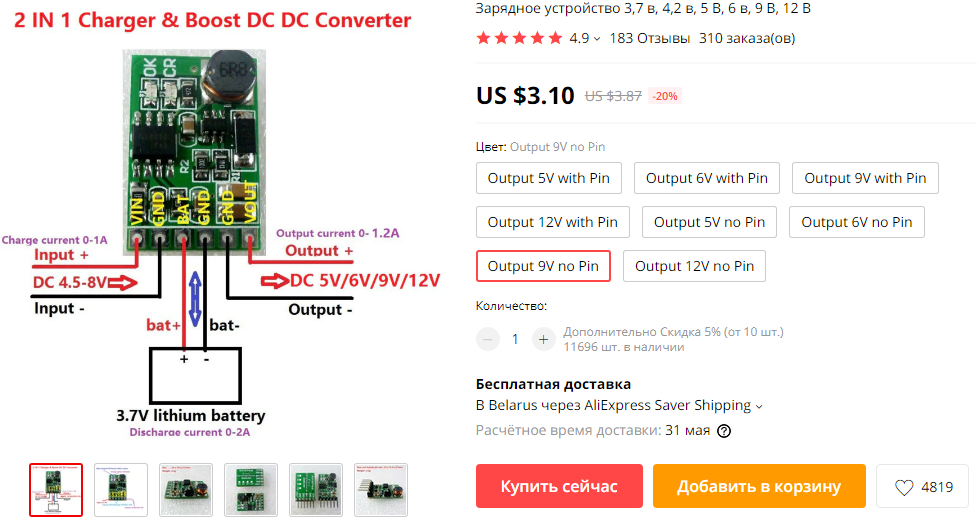

And what to connect after the motor? Is it possible to immediately connect such a charger after the diode bridge  :?

:?

Input from 4.5V. I'm not entirely sure how much the generator will give under load.

Please help me with this! Not a pro in electronics.

Answer the question

In order to leave comments, you need to log in

Where do you live that you have the wind blowing every day?

For autonomous power, it is reasonable to use a solar battery.

A wind turbine on such a motor is a bad idea, for starters it is high-speed, you will have to attach a gearbox to it, which increases it, plus the blades will need half a meter in commercials.

It will turn out to be a rather big structure that will have to be somehow firmly fixed. Plus, it will still be noticeably buzzing during operation.

Your motor is high-speed and will give you the 3W you need at 3000-5000 rpm, so you need a gearbox with a large gear ratio. Do not forget the more complex the gearbox, the greater the power loss. It is also necessary to provide for current limitation in case of gusts of wind.

If it has magnets (it attracts screws), then something like DC-DC boost Step Up converter 5v

https://aliexpress.ru/item/1005002534733447.html?s...

You take a 'regular' household uninterruptible power supply, connect an electric generator to the battery terminals through a diode bridge (by the way, choosing an engine as a generator is a separate conversation, the winding must be correct, otherwise it may turn out so that it will work at half / a third of the force or not work at all), you can also use a conventional collector motor wisely (but with it a situation is possible when it will turn the windmill and not vice versa), it is important not to make a mistake with the polarity.

By the way, experts, tell me how in this design it is the cheapest to reduce parasitic currents that discharge the battery when the engine is not running.

Unfortunately, cheap uninterruptible power supplies may not be suitable - it will be a lottery (on the forums I recommend taking uninterruptible power supplies with external replaceable batteries), plus the inverter is not designed for continuous operation there (maximum tens of minutes), but if you take it apart and add a cooling system, why not.

Then all the fuss will be with the selection of the correct gear ratio for the step-up gearbox and the area of the windmill blades. I strongly recommend a belt drive, you can assemble the simplest cone variator(google, the simplest design for low-power ones can be made by any of the city and sticks), I advise you to use a flexible rubberized cable with a round cross section and guide rollers instead of a belt to keep it from slipping. As a result, by adding feedback to the system (gear ratio control based on charge and wind force parameters), it is possible to build the cheapest and most efficient system.

As a result - the lowest price of the solution and ready-made 220v with the correct sine wave at the output. Unfortunately, the efficiency of the solution is very low.

Didn't find what you were looking for?

Ask your questionAsk a Question

731 491 924 answers to any question