Answer the question

In order to leave comments, you need to log in

What book on tolerances would you recommend?

I want to design a gear model and print it on a 3D printer, but the engine on which I plan to put it has a shaft diameter of 5 + -0.1, I don’t know what to do. And in general, it probably won’t be superfluous to read about tolerances, landings and theories of mechanical engineering

Answer the question

In order to leave comments, you need to log in

Anukhin. Tolerances and landings, for example.

And what prevents you from measuring the actual diameter and making a model of the gear using it (not forgetting about the possible shrinkage of the plastic)?

It doesn't work that way for 3D printing. There is such a print error that we are not even talking about tolerances.

"After printing, modify with a file"

What is needed to print the gear on the shaft.

1. Find a ready-made gear model, draw it yourself, or generate it according to the parameters in one of the gear generators.

2. Print the gear, check the size match with a vernier caliper, make adjustments to the print settings or the model, as the first time you probably won’t be able to get into the size due to the low printing accuracy.

3. Drill the hole for the shaft with a drill, because holes in 3D printing always turn out smaller than specified, take a slightly smaller drill, for a shaft for 5 mm, probably 4.9 will be OK. Particularly advanced use adjustable reamers.

4. Fix the gear on the shaft with superglue or a fixing screw. usually the shaft is smooth and the plastic slides well when scrolling.

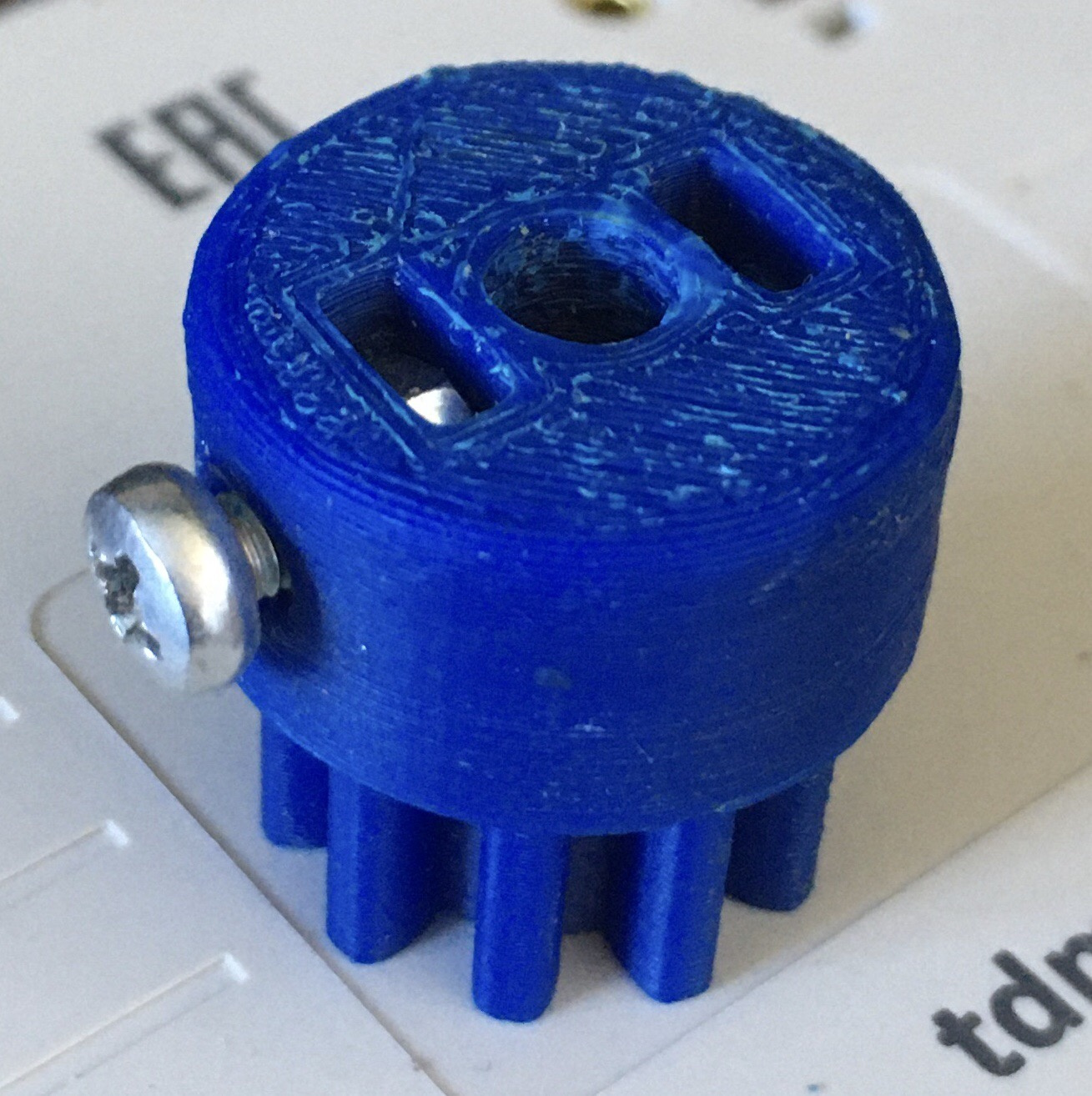

Here, for example, is my gear on a 5mm shaft, in the body of the gear there are holes into which two ordinary nuts are inserted (but it is better to look for square nuts, of course), through which two screws are screwed to fix the gear on the shaft, screws can be used countersunk, without a hat.

read - it will not be superfluous.

but also check out the 3d printing tolerances - they are quite large.

I remember the printed part with a embedded thread of ~ 50 mm diameter became 1 mm smaller ...

Didn't find what you were looking for?

Ask your questionAsk a Question

731 491 924 answers to any question