Answer the question

In order to leave comments, you need to log in

Is a 3d printer without moving parts for the home possible?

When I watched videos about 3d printing a long time ago , the idea immediately came to mind to use gravity to move the layers down.

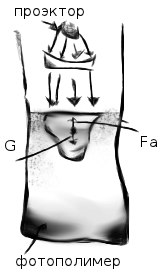

In the figure on the left: G is the force of gravity, Fa is the Archimedes force (pushing upwards out of the liquid).

Total force acting on the object: F = G - Fa. According to the law of Archimedes, the body will sink if the force of gravity exceeds the force of Archimedes, and the faster, the greater their difference.

Consider a layer of an object with thickness h_sl, area S_sl, density ro_body. The volume is: V_sl = S_sl * h_sl. Mass: m_sl = V_sl * ro_body. Gravity:

G_sl = m_sl * g = V_sl * ro_bodies * g = S_sl * h_sl * ro_bodies * g.

Strength of Archimedes:

Fa_sl = V_sl * ro_zh * g = S_sl * h_sl * ro_zh * g.

The layer will sink with acceleration:

a = (G_sl - Fa_sl) / m_sl = (V_sl * ro_body * g - V_sl * ro_l * g) / (V_sl * ro_body) = g * (ro_body - ro_l) / ro_body

where ro_l is the density of the photopolymer .

It can be seen that a is a constant depending on the photopolymer, namely, on the change in its density during sintering.

Since bodies usually sink at a constant speed, there must be a force that is proportional to the speed - this is a friction force that depends on viscosity.

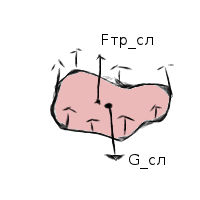

So, the speed of lowering the body depends on: the density, viscosity of the photopolymer and the shape of the body. The latter can be seen from the figure on the right. On which, Ftr_sl is the resultant friction at the layer boundaries. It can be seen that it is not attached to the center of gravity.

The advantage of using a projector is speed, due to the simultaneous acquisition of an entire layer. Another plus: the absence of moving parts, where durability, reliability, and maybe cheapness and accuracy come from. But there are also problems:

Obviously, the main difficulty lies in finding or obtaining a photopolymer with suitable properties (or relationships between properties):

Answer the question

In order to leave comments, you need to log in

Immediately I see two problems:

1) Stability. It is necessary to ensure the absolute immobility of the vessel with the photopolymer, the absence of vibrations, shocks and convection currents. Or track the position of the workpiece with high accuracy and speed (how?) And correct the exposure.

2) When the very first layer polymerizes, it will not begin to sink, but will remain hanging due to surface tension forces.

Conclusion: it's much easier to make a Z-axis drive.

Why can't a thick polymer be baked with a focused beam?

In glass, for example, they draw drawings inside with a laser ...

I forgot to add: another advantage is speed, because the layer is obtained all at once

Didn't find what you were looking for?

Ask your questionAsk a Question

731 491 924 answers to any question