Answer the question

In order to leave comments, you need to log in

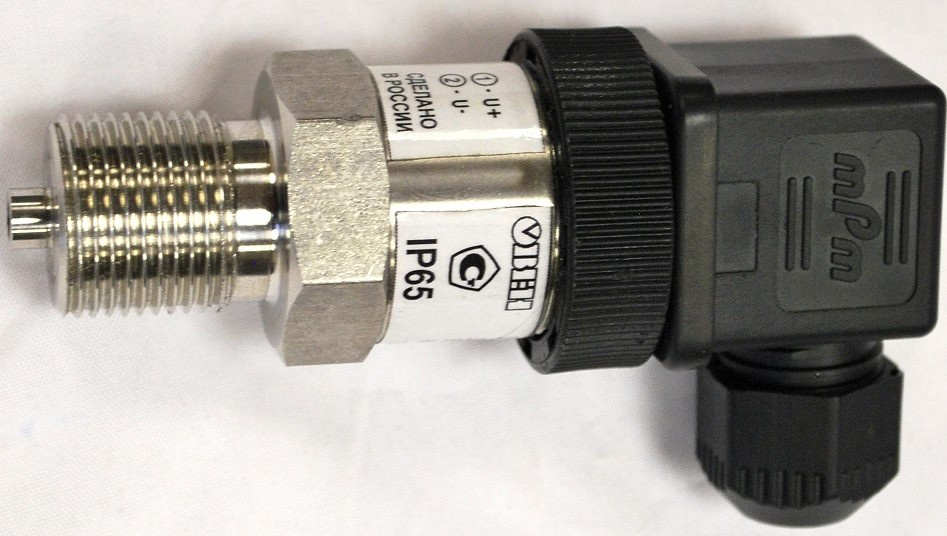

What are the minimum and necessary tools that can be used to determine the serviceability of a strain gauge pressure sensor on an object?

The sensor lies in the pressure readings, it is not clear what is faulty, either the sensor or the device. How to check the health of the sensor at the operating facility. What you need to have with you, a tester, current clamps, maybe some kind of device. it is probably best to have a device with a current input, but there may be a less expensive option.

Answer the question

In order to leave comments, you need to log in

A device with a current input is called a milliammeter and is included in the multimeter. Current clamps are also suitable, but they can have accuracy plus or minus a bast shoe.

Further conversion of milliamps into parrots can be done according to the plate in the datasheet.

Also, in order to check the sensor, you need to have at least a tee with a pressure gauge that you can trust. And then you will find out that the sensor gives out something, but if it gives out rubbish, you won’t know.

To slip a test signal into the device, you need to have a laboratory power supply, redesigned so that the current setting above 20mA was impossible.

Didn't find what you were looking for?

Ask your questionAsk a Question

731 491 924 answers to any question